Engineering Reference

Miniature & Instrument Ball Bearings

Hard Coatings

Advanced, hard-surface coating solutions increase wear resistance, reduce heat and friction, and improve bearing performance in unusually demanding customer applications. Diamond-like carbon and tungsten carbon carbide, described below, are two excellent options for extremely harmful operating conditions.

Diamond-like Carbon (DLC) and Tungsten Carbon Carbide (Tungsten-DLC or WCC)

Specialized hard, thin-film coatings, like carbon (DLC) and tungsten-DLC (tungsten carbon carbide), provide increased bearing performance when the factors responsible for life-limiting bearing wear are too extreme for standard oil- or grease-lubricated bearings.

Diamond-like carbon (DLC) and tungsten-DLC (WCC) exhibit high hardness and a low coefficient of friction over a wide operating temperature range, which contributes to high abrasive wear resistance, low heat generation, and no cold welding in poor lubrication conditions.

Both coatings possess good to excellent adhesion to bearing surfaces. This trait makes them highly resistant to flaking or chipping, with WCC offering more protection at high speeds.

Furthermore, hard coatings are corrosion resistant, non-toxic, and biocompatible, which is necessary for medical applications. Hard coatings also handle repeated autoclaving, another essential requirement within the medical industry.

NHBB’s ongoing research into different mixes of conventional lubricants and special coatings has shown that, for each specific choice, there is an optimal thickness that delivers increased tribological benefits. DLC and WCC get applied to surfaces through physical or chemical vapor deposition (PVD or CVD) to a depth of up to 5 micrometers.

Selecting the optimal thickness is a relatively simple task for most commercial uses, but it takes significant research to provide the optimal solution for unique or critical applications. NHBB is prepared to work with you to optimize the coating thickness, so it adheres properly to the substrate and delivers the required wear resistance and life expectancy. Whenever possible, we’ll try to specify a coating thickness that precludes the need to resize the parts to accommodate a new layer.

With our variety of coatings and familiarity with many different bearing environments, NHBB can provide the optimum combination of bearing design, lubricant, and coating to deliver the exact characteristics that each customer needs.

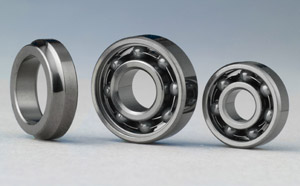

Diamond-like carbon (DLC) coated miniature & instrument ball bearings.