Rod End Bearings

Standard to specialized solutions engineered for reliability in a wide range of aerospace applications.

Design Basics

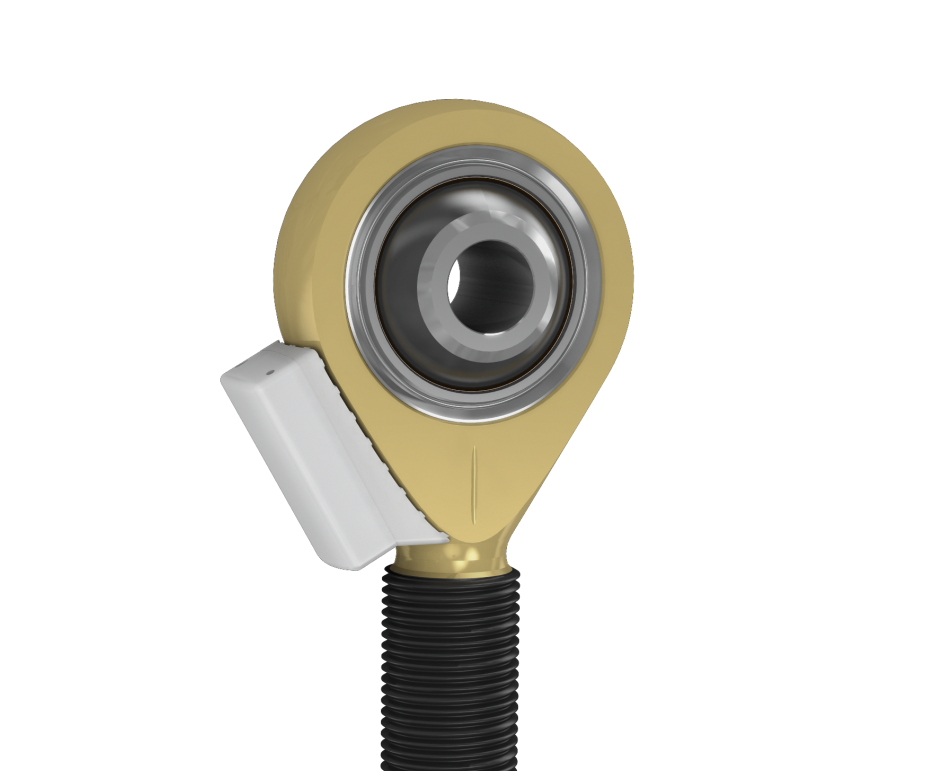

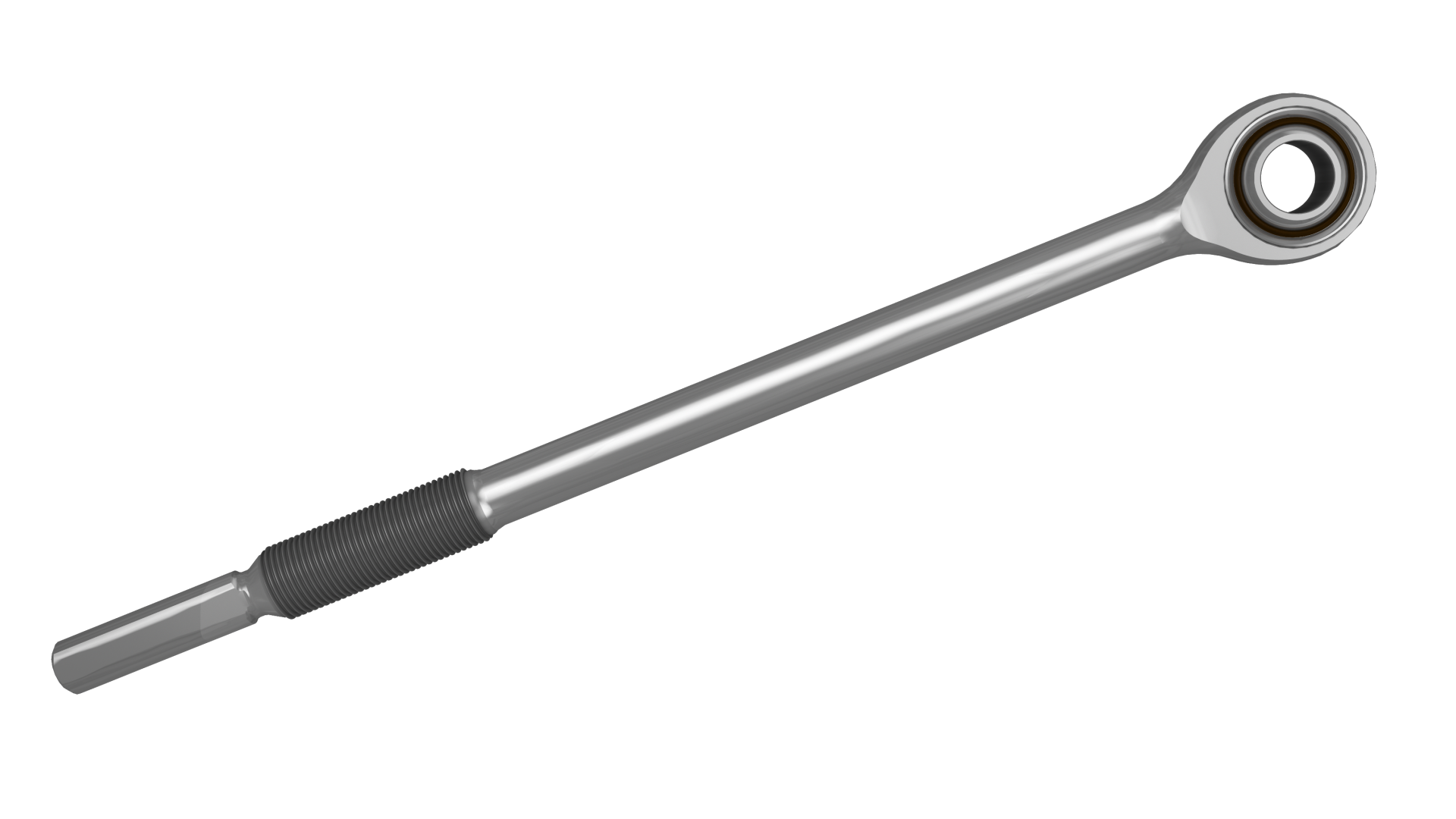

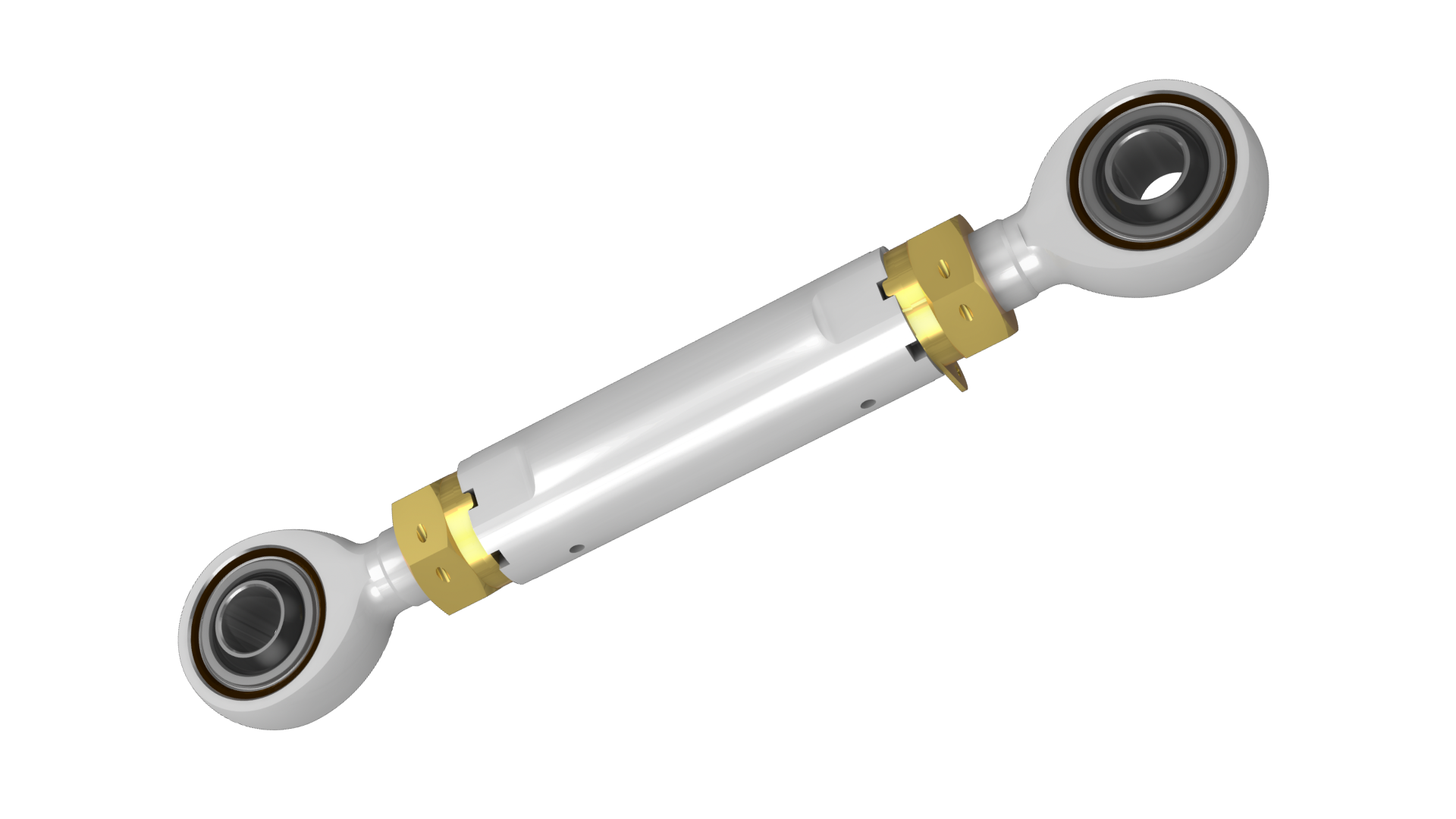

Our rod end bearings are utilized on everything from small private aircraft to the most massive long haul commercial jets. They are critical components in mechanical links and actuation systems such as engine mounts, landing gear down-lock braces, wing flap actuators, and blade pitch control assemblies. The full product family includes industry standard and customer certified bearings, complex solutions like INVINSYS® pitch link bearing system, and custom engineered solutions.

Design Options

- Full complement of rod end body types

- Premium and exotic bearing alloys

- A wide selection of patented self-lubricating liner systems

- Special surface treatments and coatings, including RoHS-compliant options

- Integral features for unlimited design options and performance improvements

Bearing Series & Types

Self-Lubricating

Corrosion Resistant Self-Lubricating

Metal-to-Metal

Loader Slot

Resource Library

Quick access to useful documents, catalogs, and other technical assistance material to help you find what you are looking for.

Bearing Customization and New Product Development

In addition to providing you with standard products, we can customize bearings to work outside the usual spectrum of load, temperature, fatigue resistance, and angular misalignment. If you are designing a new aircraft subsystem, our product engineers can assist you with bearing selection, design, and engineering.

For heightened performance challenges, our applications engineering department may involve the New Product Development Center to identify and develop a unique solution.