Engineering Reference

Miniature & Instrument Ball Bearings

Shields and Seals

Shields and seals are protective closures that retain lubricants and assist in preventing contaminants from reaching internal surfaces. When specifying a seal or shield, consideration should be given to the compatibility of the cage and enclosure type to allow for appropriate clearance. In torque-sensitive applications, it may be advantageous to use shields rather than seals because there are no contacting surfaces to create drag. The following includes the common types of shields and seals offered by NHBB. Please consult the factory for help in determining the appropriate seal or shield for your particular application.

Table of Shield and Seal Types

| Type | Description | Material | Operating Temp Max.* |

|---|---|---|---|

| Z | Shield Removable with snap wire Minimal clearance Most popular | Stainless steel 300 series | 600 °F |

| L | Seal with snap wire Provides minimal clearance to light contact resulting in low torque | Glass-reinforced PTFE | 400 °F |

| LBP | L seal with backing plate Excellent sealing characteristics | Glass-reinforced PTFE seal, metallic backing plate | 400 °F |

| D | Seal Excellent sealing characteristics | Buna-N bonded to steel insert | 250 °F |

| D1 | Seal Excellent sealing characteristics High cost | Viton® bonded to steel insert | 400 °F |

| Q | Seal, lip riding Excellent sealing characteristics | Glass-reinforced PTFE | 400 °F |

| Q4 | Seal with protective shield, lip riding Excellent sealing characteristics | Glass-reinforced PTFE | 400 °F |

*Rings and balls are heat stabilized to 300 °F.

Viton® is a registered trademark of DuPont.

Type Diagrams

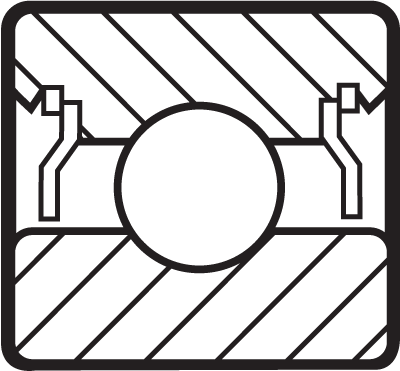

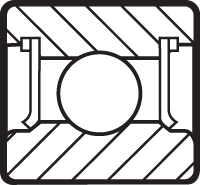

Z

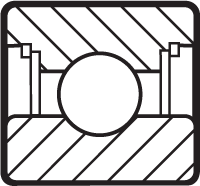

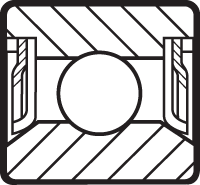

L

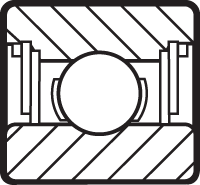

LBP

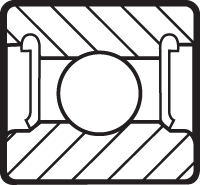

D / D1

Q

Q4