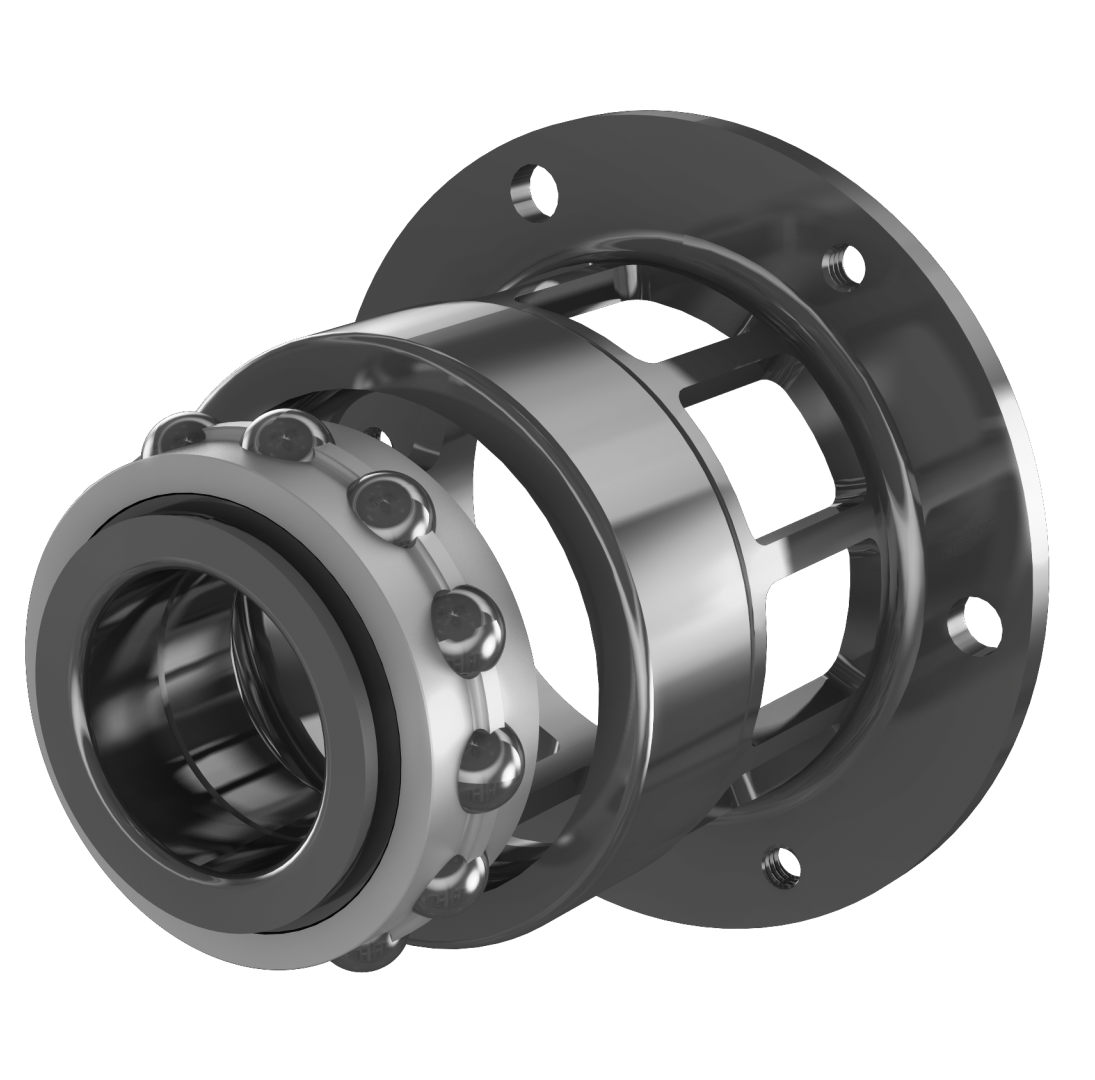

Ball and Roller Bearings

Highly engineered precision solutions for critical

aerospace systems and advanced technologies.

A comprehensive range of products and configurations:

From standard bearings to custom solutions.

Complex Bearing Assemblies

Medium to Large Ball Bearings

Medium to Large Cylindrical Roller Bearings

Miniature & Instrument Ball Bearings

Thin Section Ball Bearings

Precision Mechanical Subassemblies

Airframe Control Ball Bearings

Resource Library

Quick access to useful documents, catalogs, and other technical assistance material to help you find what you are looking for.